Plasma cutting technology used a lot in steel and metal cutting processes, especially when integrated with CNC plasma arc cutting.

What is Plasma Cutting?

Plasma cutting method is to use the heat that generated from high temperature plasma electric arc to cut the steel parts. During cutting processes, metal material will be melting and evaporated, then to use plasma power to erase the metal melting fusions.

Cutting Material Types

As Plasma cutting is a technique that cuts via electrically conductive materials using an accelerated stream of hot plasma. It could cut many types of material including different steels.

Carbon Steel

Corten Steel

Alloy Steel

Stainless Steel

Aluminum

Brass and Copper

What it is used for?

Plasma cutting is frequently utilized in auto repair and restoration, manufacturing workshops, salvage and scrapping operations, and industrial construction. Because of the very high speed and meticulous cuts coupled with low price, plasma cutting has a wide range of uses from huge industrial CNC operations all the way down to modest hobbyist shops.

Plasma Cutting Thickness

Cutting with plasma is an efficient method of slicing thin as well as thick steel plates and metal materials. Hand-held torches are able to cut steel plates as thick as 38 mm (1.5 in), and more powerful computer-controlled torches are able to slice steel as much as 150 mm (6 in) thick. Given that plasma cutters can generate an extremely hot and very focused “cone” to do the cutting, they can be invaluable for cutting metal sheets with more shapes and profiles in rounded or angled designs.

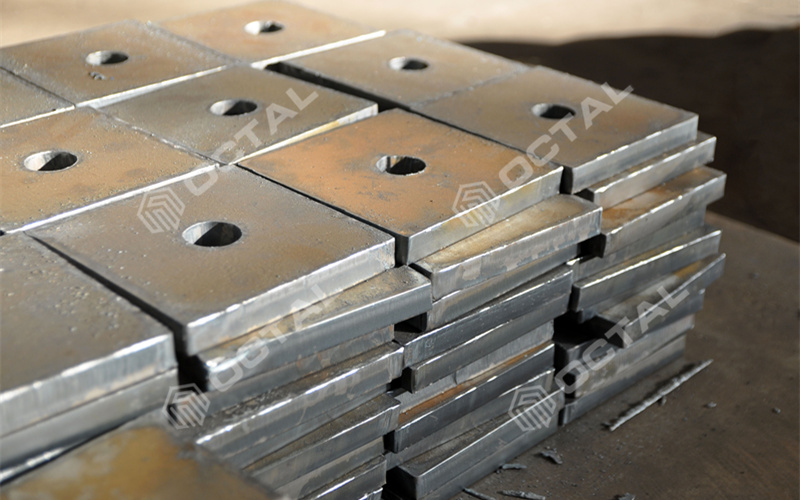

Octal provide plasma cutting services

We could provide plasma cutting as customized as below materials and size ranges:

Carbon Steel

• ASTM A36/ST37

• ASTM A516

• ASTM A537

• ASTM A572

• ASTM A573

• S275

• S355

• SPCC – Cold rolled steel

• EN8

• Galvanized steel

• Tool steel

Cutting thickness reach up to 40mm.

Tolerances +/- 1.0 mm/

Stainless Steel

• ASTM 240 304/304L/S30400/S30403

• ASTM A240 316/316L/316Ti/S31600/S31603

• ASTM A240 321/S32100

• 310S/S31008

• 321/S32100

• Duplex steel

• Inconel Alloy 625, 800, 800H, 825

• Hastelloy steel

Cutting thickness reach up to 30mm.

Tolerances +/- 1.0 mm/

Alloy Steel

Chrome alloy ASTM A387

Nickel alloy

Weathering Steel Plate (Corten steel)

• ASTM A242

• ASTM A588 Grade A, B

• Corten A, Corten B

• Weather Steel Plate

How CNC (computer numerical control) integrated in Plasma Cutting

Similar to various other machine equipment, CNC (computer numerical control) technological innovation was used on plasma cutting equipment in the latter part of the 1980s and into the 1990s, providing plasma cutting devices superior versatility to cut various designs “on demand” according to specific details which were programmed into the numerical brain of the machine.

These CNC plasma cutting pieces of equipment was, however, usually confined to cutting designs and components in flat steel sheets, employing just 2 axes of movement (known as X Y cutting)

CNC Plasma Cutting Configurations

CNC Plasma Cutting has 3 primary configurations, which are mostly differentiated by the kinds of materials before working as well as the mobility of the cutting head.

a. 2 Axis Plasma Cutting (2 D)

It is the most popular and traditional kind of CNC Plasma Cutting. Producing level profiles, in which the cut sides have a 90-degree angle to the surface of the material. CNC Plasma Cutting beds, the high powered ones, are set up in this manner, are capable of cutting profiles from metal plate as thick as 150mm all the way up to 30mm thick.

b. 3 Axis Plasma Cutting (3 D)

Just as before, a procedure for creating level profiles from a thin steel plate or sheet metal, but with the advent of an extra rotational axis, the CNC Plasma Cutting machine cutting head is able to tilt even while going through a standard 2-dimensional cutting route. The outcome of this is cut edges at angles besides 90-degrees to the surface of the material, for instances an 30-45 degree angles.

This angle is constant all the way through the material’s thickness. This is usually utilized in conditions where the profile getting cut will be utilized together with a welded fabrication as the edge angle forms a part of the weld groundwork. Once the weld preparation is carried out in the course of the CNC plasma cutting procedure, supplementary functions like milling or machining are often eliminated, thereby minimizing cost. The angular cutting ability of 3D plasma cutting can even be used to produce countersunk holes as well as chamfer edges of profiled holes.